Anchored in Thayngen, globally connected: Since 1973, Teca-Print has been manufacturing highly automated pad printing machines that are in demand worldwide. With a clear focus on quality and innovation, the company has conquered the global market while retaining its local roots.

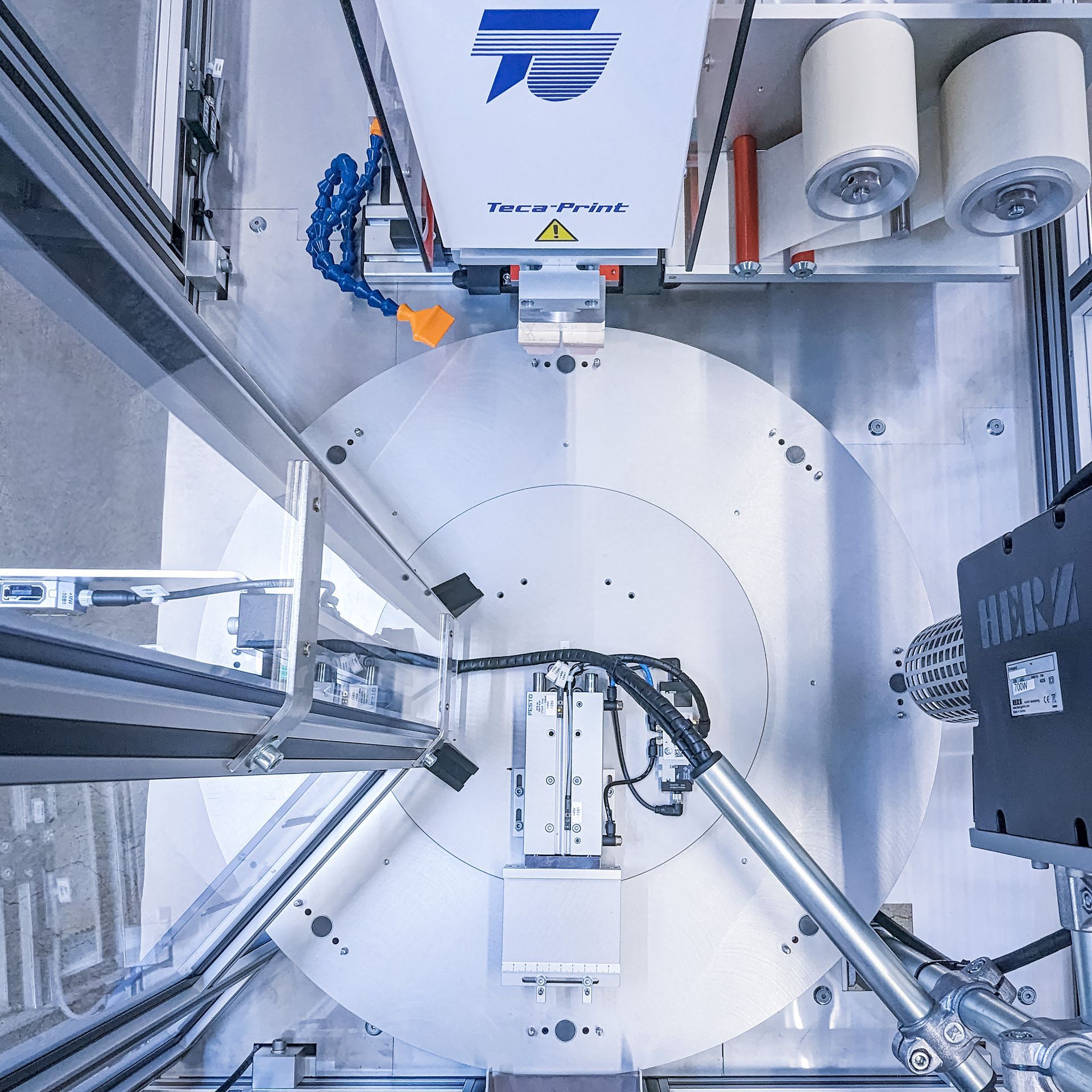

A prime example of a locally anchored, internationally connected SME is Teca-Print. Founded in 1973 in Thayngen, the company is now globally recognized for its pad printing machines. Teca-Print designs and manufactures these highly automated machines at its Thayngen location with a team of 61 employees. Pad printing is an indirect intaglio printing process, where the printing ink is transferred from the printing plate to the substrate by an elastic silicone rubber pad. The transfer of ink to the material is achieved through pressing with varying pressures. "There are some standard models from the catalog, but most of the printing systems we develop are customized for our clients," explains Managing Director Daniel Fahl. He has been with Teca-Print for twelve years, four of which as the CEO. "Our machines have a high degree of automation and the highest quality. That’s the selling point," Fahl continues. "Customers want our products because they are better—not because they are cheaper." The company’s 50 years of experience in machine development, the high quality standards Teca-Print sets for itself, its spirit of innovation, and, of course, its dedicated employees are the keys to its success. To make this work, everything at Teca-Print is done under one roof: the distance between the office and production is short, processes are well-established, and the company culture is strong. Fahl is convinced that this is noticeable to their customers.

Internationally networked

Quality is the main reason why Teca-Print's products are in demand worldwide. The machines from Thayngen can be found in countries such as Indonesia, Japan, Sri Lanka, the USA, Mexico, Australia, Israel, and of course, Europe. "In addition to our global distribution, we are also present in various industries," explains Fahl. In Switzerland, Teca-Print is closely linked to the watch industry, in Germany to the automotive industry, and in England and Ireland to medical products. The plastic industry is also a major sector worldwide. The global demand and industry diversification make Teca-Print less susceptible to economic or political changes. "Exchange rate fluctuations, a pandemic, regional conflicts, or an economic downturn in one market—thanks to our diversification, we can absorb these challenges," Fahl adds.

To ensure continued success, Teca-Print is working on further developing its machines: "We are investing in the control systems, user-friendliness, and optimization of the printing process. This results in less waste, reduced production costs, and a smaller environmental footprint." The high degree of automation in the printing machines is being enhanced with the support of artificial intelligence and new applications. "Currently, a new trend is emerging in pad printing. There is not only decorative printing but also technical printing in printed electronics. In these 'printed electronics,' conductive inks are directly printed onto sometimes highly sensitive components. This saves material, components, and time." In addition to electronics, the medical technology sector is another growth market.

To stay on top of these trends with the right offerings, Teca-Print also leverages regional networks such as ITS Schaffhausen and INOS-Coaching. "As an internationally connected company, it's essential for us to keep up with trends. The innovation events and networking with the local pool of experts in the region are very helpful. This is also because we can support each other by sharing knowledge and offering mutual assistance."

Regional embedding

The location is ideal: In addition to the company building in Thayngen, the A4 highway is nearby, and the Thayngen border crossing is in close proximity. On the other side, trains between Schaffhausen and Stuttgart pass by. The location fits well for shipping the machines and receiving materials for production. Teca-Print focuses on regionality: 90% of its suppliers come from the area. "This proximity is very important to us. It simplifies communication, which forms the foundation of a trusting collaboration." The closeness reduces transportation costs, and when challenges arise, it's helpful to know each other. "We also rely on our network and the quality from the canton: Suppliers for profiles, wood for the printing plates, or casting molds are practically produced locally." Teca-Print also has a good relationship with Altra: The employees manufacture components for the machines, and at the same time, machines from Thayngen are being processed for customer orders at Altra.